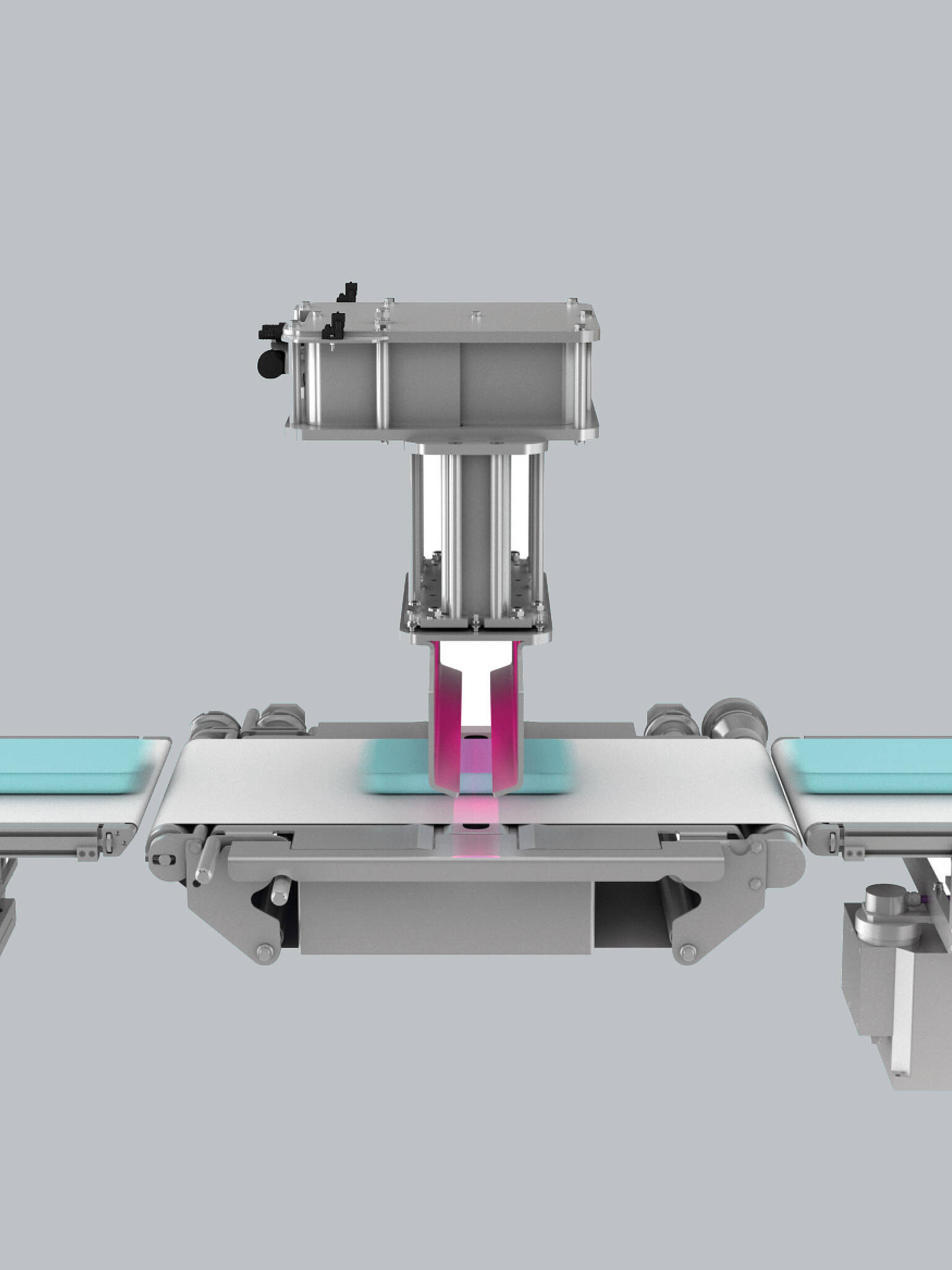

X-ray inspection systems: Comprehensive detection of foreign bodies

Our X-ray inspection systems guarantee maximum detection accuracy for a wide range of applications. They have the ability to see through packaging and detect even the tiniest foreign bodies and offer unsurpassed safety. They efficiently detect the smallest fragments such as metal, glass, stones, plastic and other materials. Our inspection solutions combine the latest inspection technology with user-friendliness and durability, and are not only precise but also fast.

At a glance: The advantages of our X-ray inspection systems:

- Precision: Reliable detection of even the tiniest foreign bodies, such as metal, glass, stone and bone

- Safety: Compliance with all relevant standards for food inspection and pharmaceutical applications.

- Efficiency: Fast inspection without production delays.

- Flexibility: Adaptable to different product types and packaging sizes.

Our X-ray inspection systems set new standards in inspection technology and offer you a comprehensive solution for your quality assurance.

Optical inspection systems: For a perfect view of your products

Our optical inspection systems are the perfect complement to our X-ray solutions. These systems inspect your products and packaging with a level of detail that cannot be achieved by the human eye, thus ensuring that your products comply with the highest quality standards. This inspection technology is ideal for detecting defective labels, seals and product forms.

Applications of our optical inspection systems:

- Label inspection: Verifying legibility, position and completeness.

- Packaging control: Detection of damage or defects.

- Color and pattern verification: Ensuring a consistent appearance.

Our optical inspection systems combine state-of-the-art camera technology with intelligent software to deliver precise and reliable results. With Wipotec’s inspection solutions, you can optimize your processes and minimize the risk of complaints.

X-ray combination systems: Solutions for maximum efficiency

Our X-ray combination systems, including the SC-W, SC-V and SC-W-V models, embody the best of our inspection technology. These inspection solutions combine X-ray technology with optical inspection technology and/or a checkweigher to ensure comprehensive product control. These systems ensure that no detail is overlooked.

Our X-ray combination systems at a glance:

SC-W: Combines X-ray inspection and checkweigher for comprehensive quality control.

SC-V: Combines X-ray inspection and visual inspection for maximum product monitoring.

SC-W-V: X-ray, weighing and visual inspection in one system.

Our combination systems are the ideal choice for manufacturers looking for maximum efficiency and comprehensive inspection technology in a single system. You save space, time and costs without compromising on quality.

Additional inspection solutions for your requirements

In addition to X-ray technology, we offer you other inspection systems and solutions to optimize your quality assurance.

Metal detection – for comprehensive product safety

Our metal detectors are specially designed to detect the smallest metallic foreign bodies in your products.

They offer maximum safety for food and other products by reliably detecting metallic foreign bodies. Our metal detection systems are an effective solution for food inspection, and can be deployed in other industries and easily integrated into existing production lines.

Label inspection and marking systems – perfection down to the last detail

Our label inspection systems and marking systems ensure that your products are correctly marked and labeled. This inspection technology helps to avoid errors and increase customer satisfaction.

Our label inspection systems work with maximum precision and reliability. They detect errors in labeling and marking before your products leave the factory, thus avoiding costly recalls. Our labeling systems are flexible and can be customized to the specific requirements of your products. Whether you need simple labels or complex markings, our inspection systems offer the flexibility you need to meet your requirements. This flexibility puts you in a position to react quickly to changes in regulations or customer requirements.

Discover the future of product inspection with Wipotec and set new standards in terms of quality and safety.

FAQ – Frequently asked questions about inspection systems

Can I integrate inspection systems into existing production lines?

Yes, Wipotec’s inspection systems incorporate a modular design and can be easily integrated into existing production lines. This means that they can be adapted to the specific requirements and space available in your production environment. Generally, integration is simple requiring minimal effort and thus avoiding production process downtimes.

Are Wipotec inspection machines easy to operate?

Yes, all Wipotec inspection systems are designed to be user-friendly and are equipped with intuitive user interfaces to ensure easy handling. This means that employees can learn how to operate the inspection systems rapidly. The user interfaces are designed to be clear and concise.

How often do Wipotec inspection systems need to be serviced?

The frequency of maintenance depends on the type of inspection system and on how intensively it is used. However, regular servicing is generally recommended to ensure the reliability and accuracy of the inspection machines.

Can inspection systems be adapted to specific product requirements?

Yes, inspection systems can be adapted to specific product requirements. This may include adjusting sensor sensitivity, modifying inspection parameters, or integrating specialized software solutions to meet the specific requirements of a particular product or industry.

How long does it take to integrate an inspection system into an existing production line?

The integration duration depends on the complexity of the system and the specific requirements of the production line.