Flexibility Unlimited

Multilane

All technical developments focus on Weigh Cells and modular multi-lane systems (MMS).

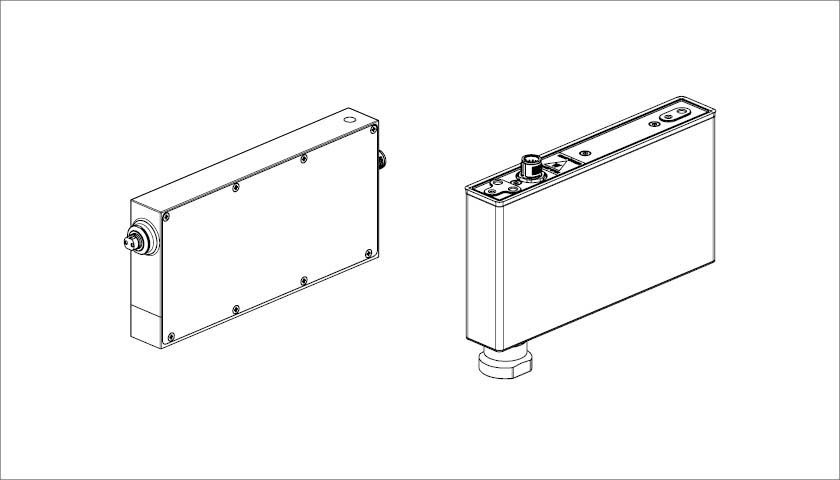

The tried and tested modular system at lane level ensures space-saving, lane-number-accurate combination of units. Individual lane modules can be arranged side by side and with precise measuring point accuracy. It requires just a few simple steps to subsequently mount the electronic modules for Weigh Cells and AVC sensor on top of them. The base module ensures the supply of operating voltage and enables connection to field bus and analysis interfaces.

Active Vibration Compensation

Filtering out Vibrations Three-Dimensionally with AVC

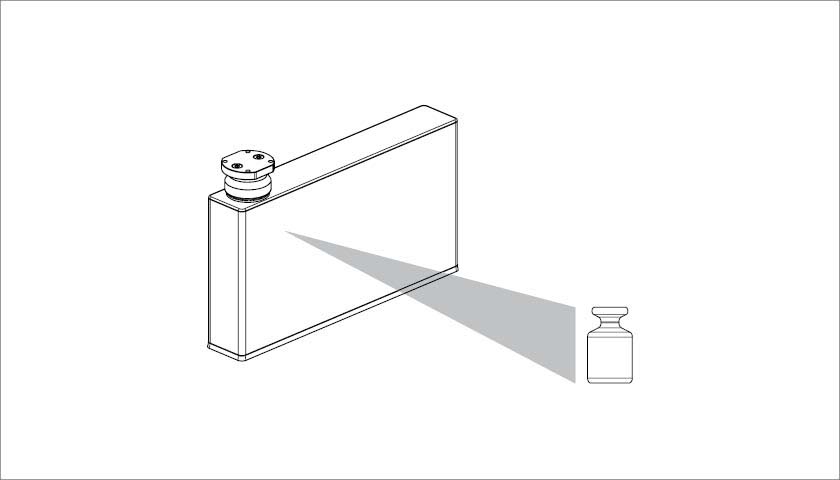

The proprietary Active Vibration Compensation (AVC), is a sensor-based measurement technology that compensates all types of vibrations in production processes. As a result, the combination of Active Vibration Compensation (AVC sensor) and Weigh Cell guarantees reliable, exact measured values even when exposed to severe vibrations, such as may occur in production plants.

Wash Down

Do you think that Wipotec Weigh Cells can’t be wet cleaned because they’re high-precision weighing systems? We’ve developed Weigh Cells that meet protection class IP65 in cleaning mode. We can even cover IP69K applications with the right Weigh Cell from our extensive range.

Mounting

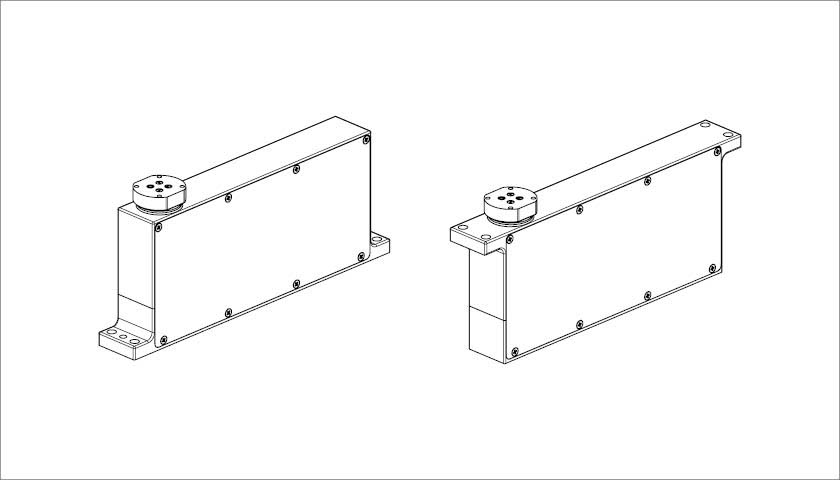

Installation options

Your machine position doesn’t permit you to screw through the mounting plate from below? This is where our mounting flange, optionally on top or at the bottom, helps with installation.

Wide variety

With Weigh Cells, the load is usually introduced from above. Do you have an innovative idea and need to introduce the load from the front? Or would you like to flip the Weigh Cells over and use them in upside down operation? You’ve come to the right place with us.

Connecting

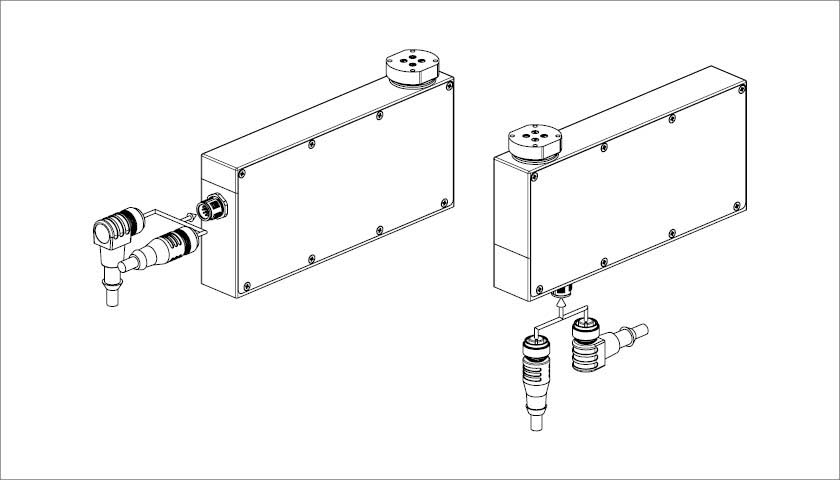

Connection options

Regardless of the installation position, the option to design the interface connection at the rear or on the bottom ensures that our Weigh Cells adapt to your machine concept. The optional straight or angled connector completes the flexible connection options.

Whether your machine communicates via CAN, RS 422, Profibus DP, Profinet IO, Ethernet/IP, EtherCAT or Powerlink, our Weigh Cells speak the same language.

Fieldbus Variety

The Weigh Cells permit communication with a large number of field buses. CANopen, EtherNet/IP, EtherCAT, Profinet IO, Powerlink are all possible. The diversity of systems ensures maximum freedom for machine constructors and end customers alike when it comes to integration in existing systems, but at the same time it also provides scope for pioneering concepts.

Self Check

Do you want to be able to check the WIPOTEC Weigh Cell is working properly at any time? For this we’ve integrated a test weight.

There is one thing about true flexibility: There are no limits.

Many advantages are good. Even more advantages are better. Provided that the customer actually recognises them as such.

Weigh Cells and their product characteristics are undoubtedly relevant for every machine and plant constructor. The big picture, however, is much more important! This is where you see that all features revolve around the Weigh Cell or the cells that are modularly combined to create a multi-lane system. This is where you see that, here too, the whole is more than the sum of its parts. This is where it becomes limitless. This is where true flexibility begins. All technical developments focus on Weigh Cells and modular multi-lane systems (MMS). The second generation of them is already available; the MMS2 is a further development of the established MMS. Implemented in protection class IP65, as far as the installation location is concerned, you are freer than ever before.

The tried and tested modular system at lane level ensures space-saving, lane-number-accurate combination of units. Individual lane modules can be arranged side by side and with precise measuring point accuracy. It requires just a few simple steps to subsequently mount the electronic modules for Weigh Cells and AVC sensor on top of them. The base module ensures the supply of operating voltage and enables connection to field bus and analysis interfaces.

The most important topic today and until harmonisation is

interface diversity

The most important topic today and until harmonisation is interface diversity. The Weigh Cells permit communication with a large number of field buses. CANopen, EtherNet/IP, EtherCAT, Profinet IO, Powerlink are all possible. The diversity of systems ensures maximum freedom for machine constructors and end customers alike when it comes to integration in existing systems, but at the same time it also provides scope for pioneering concepts. Proprietary Active Vibration Compensation (AVC) is also indisputedly a technology for tomorrow. As a result, AVC is already part of the standard equipment of Wipotec Weigh Cells. The sensor-based measuring technology compensates all types of vibrations in production processes, thus ensuring the quality of the products to be weighed – across all industries. Active Vibration Compensation filters out one-off impulse forces and/or any kind of disturbing forces, such as are reached in feed axes due to high accelerations. AVC sensors also filter out vibrations, such as those typically caused by drive units of machines or due to imbalance forces. The causes of vibrations are often application dependent. The variety of disturbing forces that can be filtered out thus illustrates the infinite range of applications for Weigh Cells with AVC sensor and their potential in Quality Assurance 4.0 in the pharmaceutical industry, food production, chemicals, logistics and many others.

Connection options

Regardless of the installation position, the option to design the interface connection at the rear or on the bottom ensures that our Weigh Cells adapt to your machine concept. The optional straight or angled connector completes the flexible connection options.

Whether your machine communicates via CAN, RS 422, Profibus DP, Profinet IO, Ethernet/IP, EtherCAT or Powerlink, our Weigh Cells speak the same language.

Design what you want and how you want it

Today, the wash down option, which is now available for both stainless steel and aluminium Weigh Cells, is also standard. Wash down means even more safety for the sensitive weighing technology and at the same time allows better performance in the cleaning processes of machines and systems. With the aid of a permanently integrated motor, the load output in the IP 44-protected Weigh Cell is closed automatically. The result: the Weigh Cell is now sealed up to protection class IP 65. Today, the aluminium version is the one preferred for multi-lane systems in the pharmaceutical industry, since the aluminium cells, which lie side by side, are enclosed again by machine constructors in line with hygienic design aspects and therefore automatically have protection class IP65. By the way, IP65 is not the highest of all classes. For special applications, Wipotec also has protection class IP69 in its portfolio.

Keyword special application

Anyone who chooses a Weigh Cell from Wipotec is also saying yes to unlimited freedom in respect of the installation options for Weigh Cells. A mounting flange is always the best solution for installation and bolting when complicated machine and system designs require slick solutions that are nevertheless space-saving and can be implemented efficiently. The connector outlet for bus and data lines can be designed optionally to the rear or to the bottom and becomes even more flexible by using a straight or angled connector.

Flexibility, however, is not required everywhere – accuracy must stay the way it is!

Weigh Cells must always deliver it along with guaranteed long-term stability. This also applies to constantly excellent responsiveness and very good linearity with fast settling times. The Self Check proves whether reality lives up to what the data sheet promises. It assists with checking that the Weigh Cell is working properly. A weight is "applied" in the Weigh Cell via software. The aim is to obtain reliable information as to whether the Weigh Cell is still working and also moves within the firmly defined limits of accuracy and, for example, drift during weighing. Same product, new batch? Simply start the self check, check that the Weigh Cell is working properly and almost immediately carry on producing with high performance. How high this performance is also depends essentially on the Sampling rate.

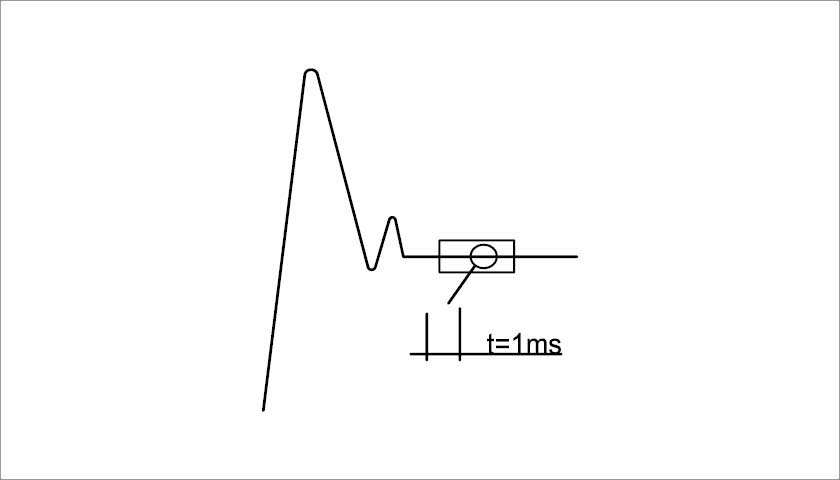

With 1,000 measured values per second, Wipotec is well above what other weighing cells in the market can achieve. This fact alone makes Weigh Cells from Wipotec the best option for companies that want to speed up their processes. The high sampling rate prevents artificial limits because it can already do much more today than the average processes require. Even with extremely high throughput rates, Weigh Cells from Wipotec determine the maximum possible number of individual weight values – 1,000 in a second!

More measured values, more precise mean values: that is 100 % inline process control with the best possible plant performance.

And this is where the circle closes. For now.

Sampling rate

A sampling rate with 1000 measured values per second makes our Weigh Cells the fastest for industrial use. At high throughputs, we determine the maximum possible number of individual weight values which ensures a precise weighing result even with short measuring times. Your task isn’t a highspeed application? No problem, there’s no harm in having more measuring points for the correct weighing result. Either way, a more precise weighing result will minimise your giveaway and help increase your machine performance.

Our weigh cell principle: fast and precise on principle

The basis of the rapid and exact working method of our Weigh Cells is the Principle of Electro Magnetic Force Restoration (EMFR). The basic principle is comparable to a simple beam balance. On request, Wipotec Weigh Cells can be fitted with AVC Technology (Active Vibration Compensation). The Active Vibration Compensation (AVC sensor) provides you with exact measured values, without any loss of time or quality, even in demanding production environments.