Product Inspection of Bread and Bakery Products: For Safe, Undamaged and Complete Pastries

Crisp crunchy bread in Germany, perfectly baked baguettes in France, awesome scones and toast in the United Kingdom. Every nation has its speciality when it comes to bread and bakery products. This is also reflected in the industry’s annual sales: with total sales of 142,168 million euros, the European market in the bread and bakery products segment is expanding. On average, Europeans spend more than €160 per person on bread, rolls and pastries, jointly consuming the formidable quantity of more than 40 billion kilos a year. Germany is the leading consumer of bread and bakery products in Europe, followed closely by the United Kingdom. Today, two thirds of bread and bakery products rattle off the baking line automatically in large bakery concerns. These industrial bakeries produce up to half a million-bakery products per day. Parallel baking lines run simultaneously in industrial bakeries in order to keep up with demand.

Even if the food is not handmade and baked by master bakers, you want to be sure that customers can bite into their breakfast rolls or packed lunch without worrying. Product inspection of bread and bakery products helps you to guarantee the safety of your bread and bakery products while at the same time monitoring optimum operation of your production lines.

On this page you will find further information on the following topics:

- Webinar: Product Inspection of Pasta and Bakery Products

- E-paper: Maximum safety in the production of pasta and bakery products

- Member of the European Hygienic Engineering & Design Group

- Challenges in the product inspection of bread and bakery products

- Quality assurance of bread and bakery products using the X-ray scanner

- The advantages of our X-ray scanners in the product inspection of bread and bakery products

- Checkweighers in the product inspection of bread and bakery products

- Hygienic Design in the Product Inspection of Bread and Bakery Products

Webinar: Product Inspection of Pasta and Bakery Products

Our experts will take 20 minutes to explain in English the advantages of inspection solutions and where they should ideally be used in the production line.

Find out in our webinar "How to Ensure the Quality of Pasta and Bakery Products", how you can:

- increase your productivity

- prevent underfilling

- protect your image

Presenters:

Joachim Ott, Business Development Manager Product Inspection

Sascha Wenz, Product Manager Checkweighers

E-paper: Maximum Safety in the Production of Pasta and Bakery Products

Reliable inspection of all types of packaging

The quality of food is becoming increasingly important. X-ray systems are the perfect solution for guaranteeing that there are no foreign bodies in the rolls, the croissants really are all filled, or that every bag of bread is closed with a clip.

Precision checkweighers can ensure that the packages are not overfilled or underfilled. Our e-paper tells you what inspection options, depending on product, packaging, X-ray scanners and checkweighers from Wipotec can offer, and where you can optimally use the solutions in your production line to achieve 100% quality of your products.

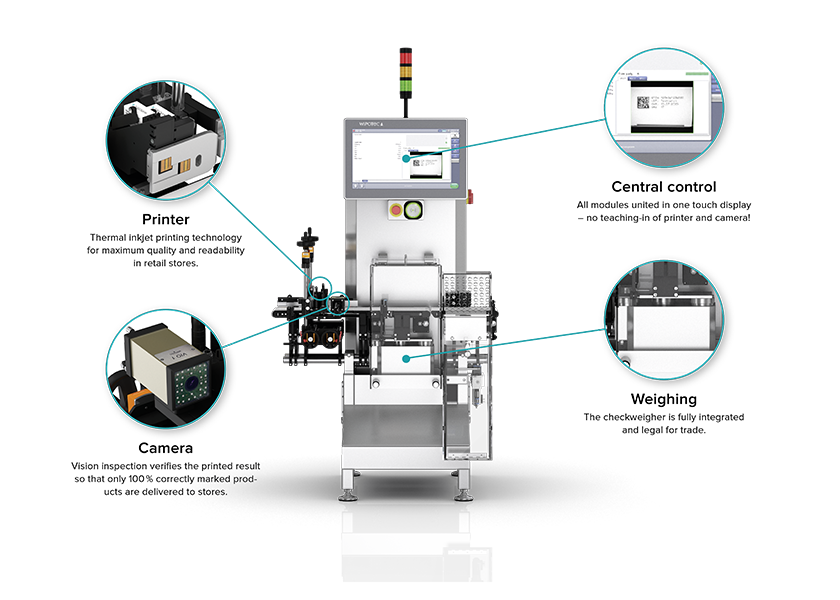

Marking, labeling and inspection

Whether by printing, laser or label: some information can only be applied to the packaging in the line. Usually these are shelf life and batch number, for which relatively simple printing systems are deployed. However, the market is developing continuously. With the introduction of dynamic 2D-Codes 2D codes for retail, this information must be coded and printed in-line. A high-resolution printer then marks the code and a camera checks the result. Without this verification, the risk of delivering incorrectly or illegibly marked goods to retailers would be far too great. After all, this code will then be scanned at the checkout.

How to mark products with 2D codes in-line

In this online event, our industry- and technology-experts

- gave an overview of the current development towards the implementation of 2D codes in retail

- explained how producers and retailers will benefit from the new marking

- discussed examples of products, packaging types and their individual challenges

- shared valuable advice to consider when marking and labeling, based on real cases

We highly recommend you to review this event, if you are

- producing packaged consumer goods or retail products in general

- taking care of the marking and labeling of your products

... but also if you are in the retail industry and want to take a look into the challenges and possibilities of your suppliers.

Challenges in the Product Inspection of Bread and Bakery Products

In the food industry in general and in the production of bread and bakery products in particular, there are challenges that must be met. The hygiene requirements in the industry are high. In industrial bakeries, freshly baked products additionally generate a massive amount of steam and dust from the mixing of ingredients. The entire baking line and therefore the checkweighers and X-ray scanners must also be easy and hygienic to clean. It is essential in a working environment that equipment meets protection classes such as IP65 or IP69K. Find out more about the hygienic design of our inspection solutions for bread and bakery products here.

Although many products are very light, the production process has to be fast and the speed of the production line is correspondingly high. Our multi-lane dynamic weighing technology prevents any bottlenecks in product inspection. Our multitrack solutions mean that several small products can be weighed and scanned in parallel at the same time, even at high belt speeds..

Quality Assurance of Bread and Bakery Products Using the X-ray Scanner

Foreign body detection in bread and bakery products

The X-ray scanner reliably and automatically detects foreign bodies that have found their way into the raw dough pieces during production. For example, these may be parts of machines that have become detached or residues in the raw materials used. Bakery products containing foreign bodies are automatically separated from the flow of goods and ejected into a rejection bin.

Foreign body detection using the X-ray scanner is more expedient than with a metal detector. The X-ray scanner can also be used to check bread and bakery products that are already packaged in metallised packaging.

Clip blanking during inspection

Bread is often packaged in plastic bags, which are closed with a metal clip. With conventional metal detectors or X-ray scanners, this can become a problem during automated product inspection. Thanks to intelligent clip blanking, the metal clip is detected but is not interpreted as contamination of the product. An assessment is also made during the inspection as to whether a clip is present at all. If it is missing and the product is not correctly closed, the appropriate product is ejected..

Completeness check

The X-ray scanner can check your baked products for completeness. Is the croissant really filled or is the hazelnut praline mixture missing? Incomplete products are detected and ejected so that production errors can quickly be rectified.

Detection of damaged products

Broken and damaged bakery products are detected immediately by X-ray inspection and ejected as waste. This means you can be sure that only undamaged and complete goods leave your baking line.

Has the dough been kneaded properly?

The X-ray scanner used for bread and bakery products discovers whether coarser ingredients like nuts or seeds are evenly distributed in bread or rolls. This gives you an indication as to whether your production is running properly and provides important information regarding the quality assurance of your production of bread and bakery products..

Label checking with the vision inspection system

Vision inspection detects whether everything has been correctly marked and labelled. With its high-resolution cameras and intelligent software, the equipment ensures that the labels are correctly positioned and labelled. The SC-V X-ray scanner checks the correct labelling of your bread and bakery products, including the sell by date and the proper labelling of allergens. Barcodes are also detected and checked for flawless printing. Our compact solution for this: the SC-V X-ray scanner with integrated vision inspection..

The Advantages of Our X-ray Scanners in the Product Inspection of Bread and Bakery Products

- Modularity permits fast, flexible solution development and integration

- Broad standard portfolio from entry-level scanners to high-performance combined devices

- High-resolution HD-TDI camera detector technology in compact designs

- Optimal application implementation via intelligent software features

- Conformity to standards such as HACCP, BRC or IFS and others

- 16-bit camera technology

- Camera detectors provide multi-resolution above a resolution of 102 µm

- Inspection speeds up to 2 m/s

Professional X-ray Inspection Using the SC-E X-ray Scanner

Our cost-efficient SC-E solution packages all the functionalities of X-ray inspection into a compact entry-level unit. With this space-saving and competitively priced solution, you can carry out completeness and breakage checks of your bread and bakery products, as well as foreign body detection. An optional software package is available that makes the SC-E a good all-round machine for mass determination, counting, filling level and completeness checks without the need for additional hardware.

Checkweighers in the Product Inspection of Bread and Bakery Products

The checkweighers of our E-M-A series check your packaged bread and bakery products for underfilling and overfilling. This ensures and documents that you comply with the packaging directive. It also prevents expensive product give-aways, and you only sell what is promised on the package. No more and no less.

The advantages of our checkweighers in the product inspection of bread and bakery products

- Wipotec EMFR weigh cells permit throughputs of up to 650 pcs/min

- Demand-oriented modularity for tailor-made applications

- Exact filling results for reducing the TCO

- Easy, user-friendly operation

- GMP conformity and hygienic design

If you need a highly compact inspection solution, we can also supply you with combination machines. Together with a checkweigher, the SC-W X-ray scanner guarantees that a package labelled “5 rolls” really does contain five rolls. Thanks to the integrated checkweigher, you avoid overfilling and underfilling your product packages, comply with the European packaging directive and remain economically efficient. A checkweigher combined with an X-ray scanner enables you to carry out many space-saving product inspections for quality assurance. The compact Modell SC-W-V gives you the added option of vision inspection. In addition to our proven checkweigher technology and innovative X-ray technology, it also includes the option of visually inspecting of the goods. Simply take a look around or let us advise you:

Hygienic Design in the Product Inspection of Bread and Bakery Products

When working with food such as bread and bakery products, you must satisfy the highest hygiene standards. Our solutions meet your requirements for hygienic design. The surfaces are easy to clean: appropriate angles of inclination and the materials used for the components and surfaces allow hygienic cleaning of the checkweighers and X-ray scanners. Our solutions of the -VA series are designed in protection class IP65 and therefore meet the requirements for frequent cleaning cycles. Since they are constructed entirely in stainless steel, the HC-A-VA and HC-M-VA, as well as EC-E-VA checkweighers can be used in light and medium humidity environments.

Solutions of the -WD series in wash-down hygiene design have been developed for intensive cleaning cycles. The robust HC-M-WD checkweigher can optionally be set to cleaning mode and with protection class; IP69K meets the stringent hygiene requirements of the food industry.

Member of the European Hygienic Engineering & Design Group

Consumer confidence is critical for bread and bakery products. For this reason, there are strict standards for food safety, and adhering to these standards is critical. For example, the EU Packaging Directive, the HACCP concept (risk analysis and critical control points), the IFS (International Food Standard), the BRC (Global Standard for Food Safety of the British Retail Consortium), the FDA, the GFSI certification (Global Food Safety Initiative) and others. As a member of the European Hygienic Engineering & Design Group (EHEDG), we are particularly committed and experienced when it comes to the production and packaging of food. We are happy to advise you on all matters regarding standards in the food industry and product inspection for the quality assurance of bread and bakery products.

Checkweighing, foreign body detection in bread and bakery products, completeness and level checking and more. With us, you get all the solutions from a single source and safeguard yourself in matters of consumer protection, packaging directives, checking standards, environmental protection, increased efficiency and prevention of damage to your image.