Product Inspection of Coffee and Tea: Efficient, Reliable, Accurate

Coffee is the undisputed favourite drink in central and northern Europe: the Finns are the front-runners with 1,310 cups per person per year, followed by the Swedes, Norwegians, Austrians and the Swiss. In contrast, the picture for tea is particularly interesting if we look beyond Europe. The favourite hot drink worldwide is not coffee but tea. Here, the highest per person consumption is not found in China, from where it originates, but in Paraguay, Uruguay, Argentina and Kuwait. Each year some 1,200 cups of tea per person are consumed in Kuwait.

What we can see is that the sales market for both hot drinks is incredibly strong. It’s one that is growing steadily. Worldwide sales amount to around 80 billion euros for coffee alone. Forecasts assume that the market volume will increase to 97 billion euros by 2023.

On this page you will find more information about:

- Webinar: Product Inspection Coffee and Tea

- E-paper Product inspection of coffee and tea

- Standards and guidelines for high food quality

- Challenges in the product inspection of coffee and tea – using coffee as an example

- The advantages of our checkweighers and X-rays for the product inspection of coffee and tea

Correct labeling of coffee and tea

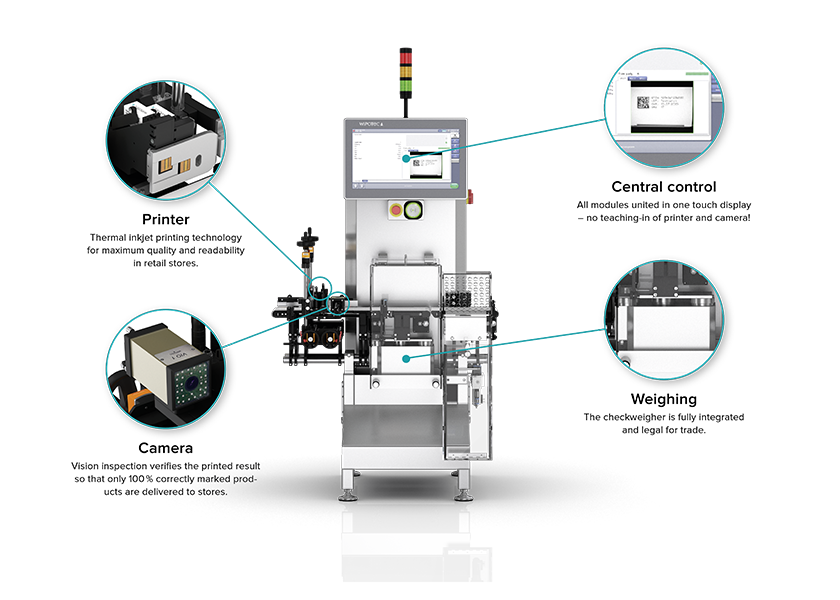

Various international regulations oblige manufacturers of pre-packaged coffee and tea to provide specific information on the packaging. There are two types of information: static content that is pre-printed in the packaging design (net quantity, ingredients, nutritional values, etc.) and dynamic content such as best-before date and batch number. The latter can only be applied during production in the form of a print or label. This is where TQS comes into play, taking on this task with minimum effort and maximum security.

For coffee and tea manufacturers, flexibility plays a major role when it comes to labeling. Today, the majority of products are generally marked with a best-before date and batch number. However, the origin of the product as well as the date and place of production are also important for transparent traceability. In-line coding is the most effective way of placing all this relevant information in a compact space. The code opens up completely new possibilities for producers, retailers and consumers:

Safety and efficiency in marking

Manufacturers of tea and coffee often process premium products in premium packaging, which is why the desire to reduce rejects and recalls to a minimum is particularly important. Product labeling and verification play a central role in this. This is why producers rely on our combined TQS units, in which all modules are fully integrated.

Benefits of full product serialization

These systems are even able to provide full serialization, i.e. the marking of each individual product with a unique serial number. This creates transparency across the entire supply chain and protects your brand from counterfeiting. For manufacturers in particular, this marking offers many advantages. Read more:

Webinar: Product Inspection Coffee and Tea

Our free webinar tells you everything you need to know about quality assurance in the product inspection of coffee and tea. We also show you the potential uses and economic advantages of high-performance checkweighers and modular X-ray scanners. Our experts deliver the 20-minute webinar in English.

Presenters:

Joachim Ott, Business Development Manager Product Inspection

Sascha Wenz, Product Manager Checkweighers

E-paper: Product Inspection of Coffee and Tea

In our e-paper “Product inspection of coffee and tea”, you will discover the options which our checkweighers, X-ray scanners and our vision inspection can offer you for the product inspection of coffee and tea. You will also see where the critical control points (CCP) are and what the perfect solution for your production line looks like if you want to achieve complete safety and efficiency.

Standards and Guidelines for High Food Quality

Consumer confidence is critical for coffee and tea. For this reason, there are strict standards for food safety that must be adhered to. For example, the EU Packaging Directive, the HACCP concept (risk analysis and critical control points), the IFS (International Food Standard), the BRC (Global Standard for Food Safety of the British Retail Consortium), the FDA, the GFSI certification (Global Food Safety Initiative) and others.

As a member of the European Hygienic Engineering & Design Group (EHEDG), we are particularly committed and experienced when it comes to the production and packaging of food. We are happy to advise you on all matters regarding standards in the food industry and product inspection for the quality assurance of coffee and tea.

Checkweighing, foreign body detection in coffee and tea, completeness and level checking and more: with us you get all the solutions from a single source and safeguard yourself in matters of consumer protection, packaging directives, checking standards, environmental protection, increased efficiency and prevention of damage to your image.

Challenges in the Product Inspection of Coffee and Tea

- As a manufacturer, with an expensive product like coffee you have to be sure that the quantity filled is exactly right. Our checkweighers will make sure for you.They weigh all types of packaging accurately and reliably, whether capsules, pods, sticks or pouches.This allows you to prevent overfilling and increases efficiency.

- While overfilling may result in economic loss, underfilling leads to loss of image which is an equally important challenge. The German Pre-packaging Regulation permits only a very small tolerance between the weight printed on the packaging and the actual contents of the product. As a result, our checkweighers not only weigh accurately, they also communicate with the filler. In the event of a fluctuation, the filler receives the information and adjusts the quantity filled accordingly.

- During foreign body detection in coffee, both vertical packaging and also jars can be inspected easily. You can use our SC-S X-ray scanners for this.

- Foreign body detection is particularly important in coffee. If stones get into the coffee mill of automatic coffee machines, they can damage what is often an expensive unit. This is very annoying for the consumer. But downstream producers also don’t want any foreign bodies in the coffee. You can ensure this with our innovative and reliable SC-B X-ray scanners which examine the beans for foreign bodies before packaging.

- The X-ray scanners of the SC series reliably check packaged products, whether horizontal or vertical, for foreign bodies and other quality features.

- A complete product inspection of coffee and tea also includes the checking of barcodes, texts such as sell by date and contents as well as labels. Our compact solution for this: the SC-V X-ray scanner with integrated vision inspection.

The Advantages of Our Checkweighers for the Product Inspection of Coffee and Tea

- Wipotec EMFR weigh cells permit throughputs of up to 650 pcs/min

- Demand-oriented modularity for tailor-made applications

- Exact filling results for reducing the TCO

- Easy, user-friendly operation

- GMP conformity and hygienic design

If you need a highly compact inspection solution, we can also supply you with combination devices. TheSC-W, for example. It combines our high-precision checkweigher with the modular X-ray scanner. The HC-M-MDi checkweigher additionally offers an integrated metal detector on the smallest footprint. For the heavy-duty and secondary packaging sector, the HC-M-SL is an excellent solution. Simply take a look around or let us advise you:

The Advantages of Our X-ray Scanners for the Product Inspection of Coffee and Tea

- Modularity permits fast, flexible solution development and integration

- Broad standard portfolio from entry-level scanners to high-performance combined devices

- High-resolution HD-TDI camera detector technology in compact designs

- Optimal application implementation via intelligent software features

- Conformity to standards such as HACCP, BRC or IFS and others

- 16-bit camera technology

- Camera detectors provide multi-resolution above a resolution of 102 µm

- Inspection speeds up to 2 m/s