Advanced Case Labeling Technology

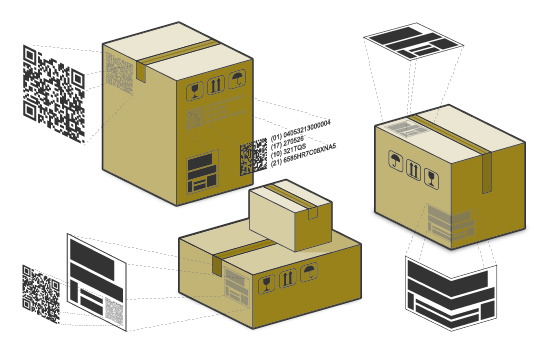

Accurate case labeling systems are essential for ensuring smooth operations and supply chain compliance. Whether for logistics standards or meeting the digitalization needs of retailers—such as including QR codes or Data Matrix codes—labeling plays a crucial role. Our advanced case labeling solutions ensure your processes are efficient, error-free, and compliant with all industry standards.

On this page, learn more about how our case marking systems can help your business:

Key Features and Benefits of Our Integrated Case Labeling Systems

- Unified Control System: Streamline your case labeling operations with a single system that integrates transport, marking, labeling, and inspection, reducing complexity for operators.

- Enhanced Efficiency: Our turnkey case coding systems come pre-synchronized, ensuring seamless integration between conveyors, printers, and labelers. This eliminates delays and increases throughput.

- Modularity for Flexibility: Our systems are modular, allowing you to tailor them to meet your specific case marking requirements. Easily adjust parameters to accommodate different products, helping you stay agile in a dynamic market.

Quality Assurance and Labeling Compliance

Maintaining quality and compliance is critical in any labeling process. Our case labeling systems include inspection cameras that verify:

- Legibility: Ensure all label information is readable and meets regulatory requirements.

- Optical Quality: Avoid labeling issues like mixed-up labels, nipped corners, or wrinkles that can affect product integrity.

- Print Apply Verify: Our case label verification system ensures accurate and consistent labeling.

Reliable Case Traceability Solutions

Our advanced labeling systems offer optional serialization and aggregation, key components in modern supply chain management:

- Unique Identification: Utilize SSCC (Serial Shipping Container Code) numbers for accurate identification of each case in the supply chain.

- Simplified Inventory Management: Aggregation links individual products to cases and cases to pallets, making it easier to manage inventory and handle recalls efficiently.

Embrace Direct Marking Technology for Case Labeling

Discover the future of packaging with our innovative direct marking technology, which allows for labeling without adhesive labels. This advanced technology uses solvent and water-based inks to print high-quality information directly onto cases, delivering superior results even on non-absorbent surfaces. Many companies are unaware of the innovative benefits that direct case marking offers compared to traditional labeling methods. Our direct marking technology provides a range of advantages that are rapidly making it the preferred method in the packaging industry.

Key Benefits of Direct Marking Technology

- Cost Savings: Eliminate the need for adhesive labels, reducing material costs and minimizing waste in your labeling process.

- Faster Processing Speeds: With direct marking, you can achieve higher throughput rates without the complications of applying physical labels.

- Lower Maintenance: Direct marking reduces the number of components, meaning less maintenance and reduced downtime in your operations.

- No Label Storage and Inventory Management: By eliminating physical labels, you simplify logistics and reduce the costs associated with storage and inventory management.

- Easier Print Layout Changes: Adjusting print layouts is far more flexible and efficient compared to changing traditional labels, providing agility in your packaging processes.

- No Peeling, Creasing, or Wrinkling: Avoid common issues associated with adhesive labels, such as peeling, creasing, or wrinkling, by adopting direct marking technology.

- Compatibility with a Wide Range of Surfaces: Direct marking works on various materials, offering flexibility for different production environments and packaging types.

Case Labeling Essentials

The manufacturer’s guide to efficient end-of-line performance

Whether there are legal regulations to fulfill or retailers requiring special contents like a Data Matrix or QR code – accurate labeling is crucial for operational success. This guide provides a detailed look into our latest advancements in case labeling technology, highlighting key features, benefits, and applications. Whether you’re upgrading your current system or exploring solutions for a new production line, this guide will help you navigate the options and make informed decisions.

Optimize Your Case Labeling with Advanced Technology

- Our case labeling systems integrate cutting-edge technology with modular design, ensuring flexibility, efficiency, and compliance with all relevant standards. Whether you're looking for direct marking solutions, enhanced traceability, or fully automated case labeling systems, we have the technology and expertise to meet your needs.

- Contact us today to learn more about our innovative case labeling and marking solutions and how they can streamline your operations.