Applications of Dynamic Weighing Systems in CEP, Postal Industry and Intralogistics

Dynamic weighing technology enables global Courier, Express, Parcel (CEP), Postal, and Intralogistics providers to acquire precise package weight information in high-speed shipping, warehousing and e-commerce applications. Precision parcel weights acquired as packages move at high speeds maximises operational efficiency, while increasing billing accuracy. The bottom line for CEP, Postal, and Intralogistics providers is that efficient dynamic weighing systems increase their profitability, while enabling them to increase shipping accuracy, and deliver world-class customer service.

On this page you will find more information about:

- Dynamic weighing systems in Courier, Express, Parcel (CEP) industry

- Dynamic weighing systems in the postal industry

- Dynamic weighing systems in intralogistics

Dynamic Weighing Systems in Courier, Express, Parcel (CEP) Industry

Before the explosion of online shopping, i.e. e-commerce, the CEP industry mostly concerned itself with traditional B2B companies. These companies generally had defined package sizes and weights with simple, low volume, non-palletised small package shipping requirements. When B2C e-commerce companies started selling and delivering anything, to anyone, located anywhere in the world the industry’s shipping requirements became far more complex.

In order for the e-commerce industry to survive and thrive the Courier, Express Parcel industry had to implement new parcel weighing, dimensioning and package handling technologies to manage an exponential increase in the complexity of small parcel (50 kg or less) shipping volumes. Implementing new dynamic weighing systems enable CEP providers to handle both the volume, accuracy, shipping speeds, and package size diversity now common in the e-commerce and shipping logistics industries.

- Less time spent weighing and sorting means faster parcel deliveries

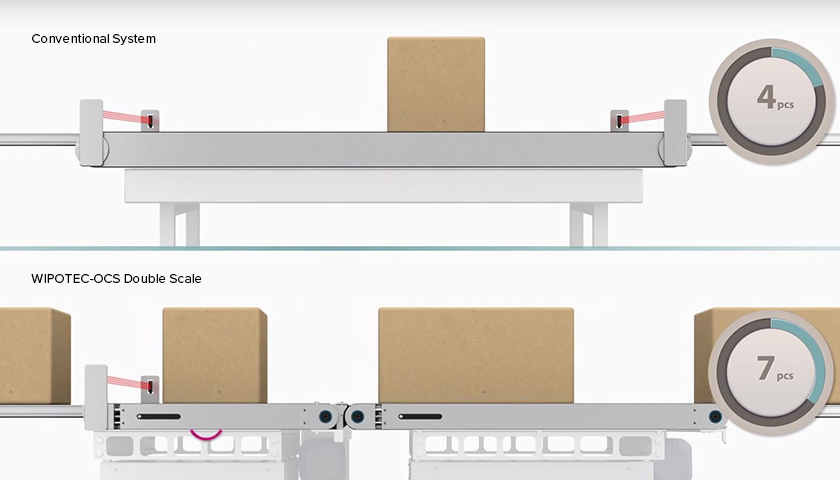

- Double scale operation enables greater package flexibility

- HC-FL-2 multiscale design delivers 60% greater throughput compared other single-interval scales

Application of dynamic weighing systems in CEP

Dynamic weighing scale for small to midsize parcels

The EC-M Smalls scale has been deployed in many different small parcel, package and letter/flats applications in e-commerce, courier express, and parcel/postal applications. Manufacturing and automated work-in-process applications with item weights under 15 kg and transport speed less than 1.2 m/s can also benefit from the robust design and economical price point.

Dynamic weighing double scale for midsize to big parcels

The HC-FL-2 multiscale, oftentimes called the double scale, delivers certified high-speed parcel weighing throughput with increased package size and spacing flexibility in CEP applications. The double scale array of single-interval scales making up the multiscale can work independently or in tandem. Independent scale operation happens automatically with smaller packages. This allows two smaller packages to be weighed simultaneously, while extremely long packages are weighed with the two dynamic weighing scales working in tandem. This inherent double scale advantage results in faster parcel sorting throughput, with more accurate package weights, and delivers enhanced revenue possibilities for the CEP provider. Speed and performance is what it’s all about when it comes to deploying dynamic weighing scales.

Application of dimensioning weighing scanning systems (DWS) in CEP

DWS systems provide significant cost benefits to CEP (Courier, Express, Parcel) providers.

DWS – dimensioning weighing and scanning systems – scan individual package labels while capturing accurate package weight and dimension information. In a DWS application it is all about accurately capturing the correct package weight and tying that weight to the correct customer in order to accurately bill the customer for the package delivery service. Correctly connecting a specific package’s shipping label to an accurate package weight provides CEP provider with several revenue enhancement opportunities including:

- Reduction in billing errors

- More precise package weights provides more accurate transport fees

- Specific package weights and label data connected together enhances freight asset

Dynamic weighing systems in the postal industry

The dynamic letter scale from Wipotec is a key weighing system component in many worldwide mail processing and distribution centers, including the Sectional Center Facilities (SCF) of the United States Postal Service (USPS). Up to three of our letter scales can be connected in parallel to deliver a throughput rate of up to 60,000 letters per hour. In postal applications in the EU, the Wipotec letter scale is MID approved for high-speed letter scale applications.

Ease of machine integration into a vertical dynamic letter weighing system is a major application advantage of the Wipotec dynamic letter scale design. The patented letter transport of our letter scale will not allow letters to jam, but allow the letters to freely stand lengthwise to enable high-speed weight capture. Different transport systems are available to handle letters or flats.

Postal mail sorting center speed and dynamic weighing system accuracy requirements, even in these high vibration environments, are not a problem for the Wipotec dynamic letter scale. This long-life letter scale is built to withstand the rigors common in letter processing and distribution centers.

Dynamic weighing systems in intralogistics

The term “logistics” is basically how a shipping company moves any package from point A to point B. While “intralogistics” means using logistics technology and best practices to efficiently move packages from the receiving dock to the shipping dock inside a manufacturing plant, or a fulfillment or distribution center. Intralogistics optimizes the logical flow of parcel shipping information and the packages themselves inside a facility.

As in logistics, catching package weight and dimension information quickly and accurately is critical in intralogistics. Catchweighers, i.e. dynamic weighing scale, and package dimensioning systems capture package weight and size information dynamically as the packages are received and this information is merged with the package labeling information. This combined package information is used by the control system to either store the package in an optimum location for later use and shipment, or to immediately move that package to where it is needed either inside or outside the facility. Dynamic weighing technology and package dimensioning systems provide the critical weight and package size information needed by any intralogistics system to maximize organizational efficiency and profitability.

Application of dynamic weighing systems in intralogistics

Dynamic weighing warehouse scale for light to midsize freight

The HC-Warehouse dynamic weighing scale is optimized for use in intralogistics applications. In the case of incoming goods in a warehouse; the weight and package information of the goods needs to be properly captured and managed to ensure warehouse operational efficiency. The same is true for catchweight applications in production, final assembly and order picking. A dynamic weighing scale such as the Wipotec’s dynamic weighing warehouse scale is and economical solution for these applications where the package or item weight range is less than 35 kg and the nominal transport speed is less than 1.2 m/s.

Dynamic weighing systems for midsize to heavy freight

Dynamic weighing system from Wipotec, oftentimes called catchweighers, are industrial weighing scales available in a wide variety of configurations suitable for many different catchweight applications. There are different models of mid-range dynamic weighing systems available that accept product weight ranges of 30 kg, 60 kg and 150 kg. These single interval scales are used in a wide variety of catchweight applications in warehousing, tire manufacturing, work-in-progress sub-assembly parts weighing, and package shipping and distribution. Great product match for dynamic weighing system is in applications where the industrial weighing scale needs to handle sacks, large bags, and canister package form factors. Examples of this type of packaging is fruit and vegetable produce, dog food, animal feed, and building materials such as paint, and chemicals.

Application of Dimensioning Weighing Scanning Systems (DWS) in Intralogistics

DWS systems provide significant system enhancements in intralogistics, and e-commerce and warehousing applications.

Manufactured goods received at order fulfillment warehouses commonly found in intralogistics, logistics, and e-commerce applications use DWS systems to scan and weigh the incoming goods. This identifies the specific product and its associated weight to the warehouse control system which uses that information for a variety of purposes including the goods storage location within the warehouse. Outbound customer orders also go through a DWS system to ensure proper shipping tracking and transport fee assignments similar to the CEP application.

Intralogistics, e-commerce, and logistics system enhancements provided by DWS systems include:

- Accurate location and weight data for individual goods

- Faster order picking and customer fulfillments results in increased customer satisfaction

- Increased product tracking information and improved billing accuracy

Dimensioning Weighing Scanning Systems (DWS) for Bulky Freight

Bulky freight, sometimes called oversize freight, includes items such as furniture, bedding, and other household goods sold on-line by e-commerce companies such as Amazon, IKEA, Wayfair, Crate and Barrel and big-box stores. Deliver companies such as FedEx, DHL, and UPS are implementing Dimensioning Weighing and Scanning systems to handle the “final-mile” deliver of these bulky freight items. Bulky freight deliveries driven by e-commerce is currently a $3.7 billion a year business and is project to be a $12b business within ten years. Bulky freight in the B2C e-commerce industry is the fastest growing shipping and logistics segment.

Using a DWS Irregular system to manage bulky freight lessens the special handling needed for these oversize items. Capturing the weight and dimension information from the bulky freight items on a dynamic basis helps to automate the billing process for items weighing up to 150 kg. Accurate capture of weight and size information increases shipping accuracy while lowering material handling costs.