Innovative product markings using RFID technology

In order to meet the demands of highly specialized industries, markings need to provide more information at a faster pace. In the pharmaceutical industry, for example, strict regulations on the serialization of pharmaceuticals have been in force for years, and the distribution of medical devices in Europe has long required absolute end-to-end traceability throughout the supply chain, as summarized in the latest guidelines for Unique Device Identification.

Here, as everywhere else where the printing of text or code is no longer sufficient, it is advisable to use advanced technologies that automate a wide range of processes and provide additional transparency in the handling process. Companies around the world rely on innovative RFID systems for this purpose. This is because using contactless radio signals is ideally suited to marking products with dynamic and static data whose verification must be as reliable as it is fast.

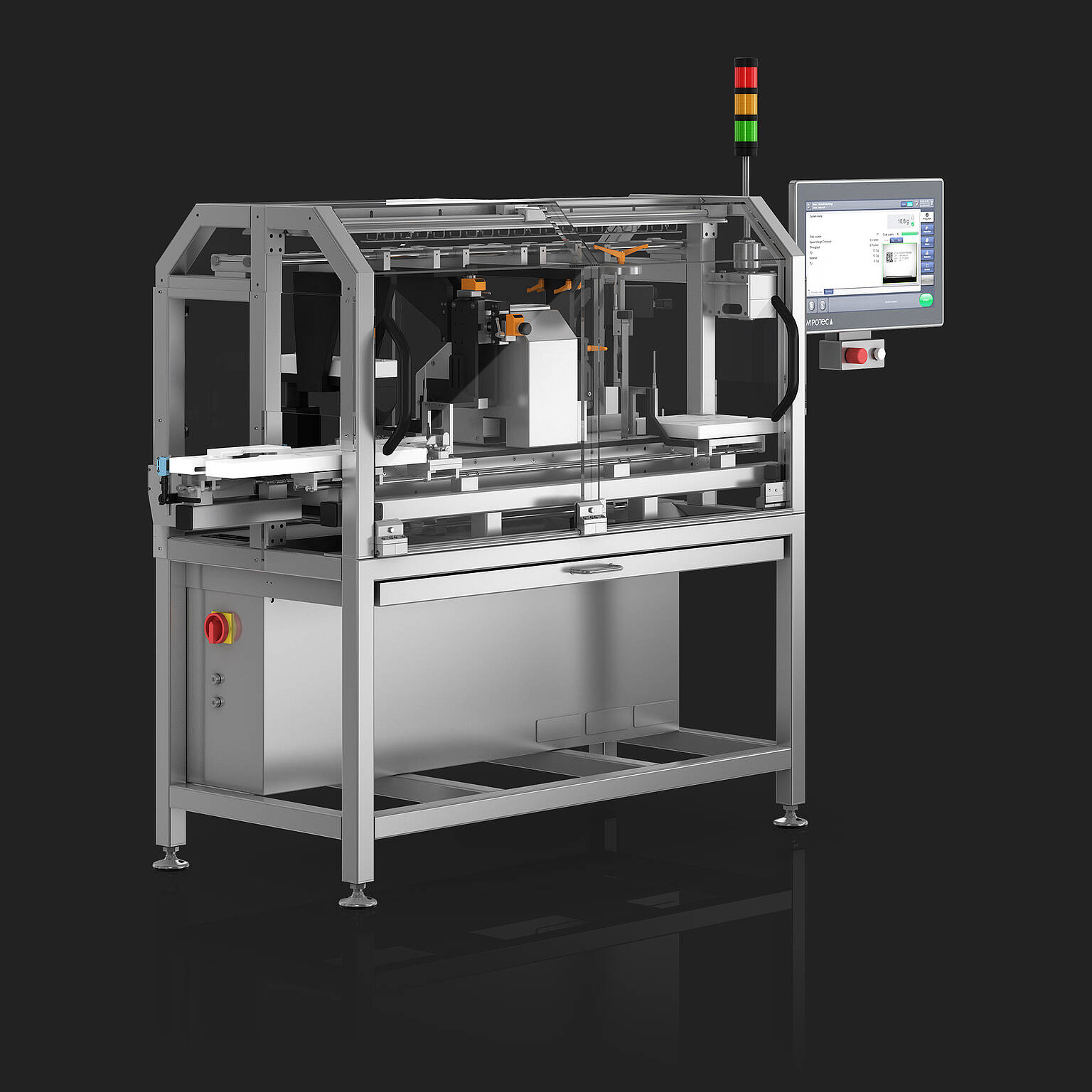

The possibilities of RFID technology are available to companies when you integrate a device for marking products into your production line. We are happy to equip our Traceable Quality System with the appropriate modules on request. Due to the modular design of TQS, you will receive exactly the configuration you need to mark and verify your products.

At Wipotec everything comes from a single source: there are no separate components, rather a holistic system whose different elements are matched perfectly. Furthermore, your company has one single partner handling maintenance and other services who is available at all times.

Advantages and functions of RFID

The abbreviation RFID stands for Radio Frequency Identification technology. A special transponder (RFID tag) contains a chip with an antenna that transmits the selected data to a dedicated reader. For marking products, these tags are attached mainly in the form of labels. With TQS, an RFID module takes care of writing and reading the contents so that verification is never missed before the end of the line. Insufficiently marked articles are separated using a rotary ejector.

Equipping vials and flasks with RFID

For manufacturers who need to identify individual products with absolute reliability, the implementation of an RFID solution shows huge potential. For example, when a liquid is filled and a flask is tagged, authorized personnel should be able to easily determine its contents. Automation in your facilities can be boosted by strategically placed readers. For this reason, Wipotec supports RFID solutions as an integral part of our advanced TQS solutions. Specifically, the RFID module optimally secures vials containing vaccines or other medicines against tampering and can be an efficient solution for protecting medicines from counterfeiting.

RFID, marking and optical inspection combined in one system

- Even before separation, the filled containers pass through the system’s first control point, which gently separates any flasks that have toppled.

- This is followed by printing – on the top of the cap or on the side of the label, in code or plain text, visible to the naked eye or concealed by UV ink.

- The special feature of this configuration is the addition of an RFID transponder, which additionally reads serialized data from the label.

- Following marking, two types of visual inspections take place: A color camera checks from above whether the vial cap is the correct color, and another module verifies the printed marking.

- Defective products are ejected accurately and gently to avoid damaging the glass containers.

The printer, camera and RFID unit are fully integrated. So if settings are changed or data added via the central user interface, each module receives the same information in real time. Accordingly, the RFID device can transfer these data to a tag or, alternatively, read out already existing signals. The system properties are the first priority.

Digitization taken further: RFID in the healthcare sector

The demand for RFID technology to accurately identify medicines and medical devices is growing.US hospitals in particular require tried and tested solutions from their suppliers to increasingly automate the day-to-day workflows involved in treating patients. With the help of the TQS module, Fresenius Kabi therefore adds practical RFID smart labels to shipments of goods for medical professionals. Experience has demonstrated that a holistic concept using RFID for marking and verification of products can form the basis for all future digitization measures.

The application provides detailed seamless documentation when handling medicines. By scanning the RFID tag, it should be clear at all times what medicine and what dose has been administered to the patient, or even which medicines are soon approaching their expiry date. Until now, such data had to be entered and corrected by hand – in wards above a certain size, this occurred hundreds or thousands of times a day. An automated system saves an immense amount of effort in this area and lets employees stay focused on their actual core tasks. One of the major advantages of RFID is in fact being able to verify entire batches in a single step. Never has it been possible to create inventories faster.