Compatible! Modular weighing and inspection technology

Wipotec provides stand-alone weighing and OEM integration solutions tailored exactly to your machines and line requirements. Primary target industries are the food and pharma sector; however we support machinery manufacturers delivering the best machines and lines for various other industries. Our checkweighers are built to increase your performance by delivering the highest throughput and accuracy. The track & trace solutions marketed through our TQS (Traceable Quality System) brand specifically aim towards the needs of pharmaceutical manufacturers in light of numerous existing and emerging global serialisation requirements. With our expert service and the low maintenance requirements of our systems, we ensure that you and your customers are highly satisfied from the start.

Find out more about the range of applications of Wipotec weighing and inspection technology in the machine manufacture.

- Precise compact checkweighers and weighing solutions

- Highest throughputs due to Wipotec EMFR weigh cells

- Flexible integration thanks to a modular portfolio with open interfaces

We offer high-performance weighing solutions

In view of the fierce global competition, machine manufacturers are dependent on competitive weighing solutions. Our Checkweighers represent a cutting edge technology allowing you to maintain your competitive advantage. With constantly high belt speeds and the smallest object spacings, the weigh cells determine the exact weight value at lightning speed. We are renowned for compact integration into your machines or production lines.

As space-saving devices integrated into your packaging machines, our checkweighers with Wipotec Weigh Cells measure the exact filling weight of packages and send the data to your output devices. Thanks to this information, filling quantities can be regulated without wasting time and packages with the wrong weight can be ejected. The high measuring accuracy of the Wipotec Weigh Cell and checkweigher is optionally supported by Active Vibration Compensation (AVC) by filtering out disturbing vibrations and shocks in the environment. AVC thus enables Wipotec weighing technology to be used even in environments that are not free of vibration, and the active compensation process does not affect either the accuracy or the product throughput.

TQS - Flexible Track & Trace Solutions

With TQS (Traceable Quality System) we provide a state-of-the-art Track & Trace solution for packaging lines in the pharmaceutical industry. These systems permit the complete traceability of medicines along the entire supply chain. This feature will make a significant contribution to the safety of medicines according to the requirements of several national regulations, e.g. the EU Falsified Medicines Directive coming into effect February 2019 and supports the exposure of pharmaceutical counterfeiters. The TQS portfolio comprising stand-alone and integration solutions that adapt flexibly to your application requirements. Whether you are looking for a serialisation machine or an integrated aggregation solution for a case packer, we are the right partner for you.

Serialisation

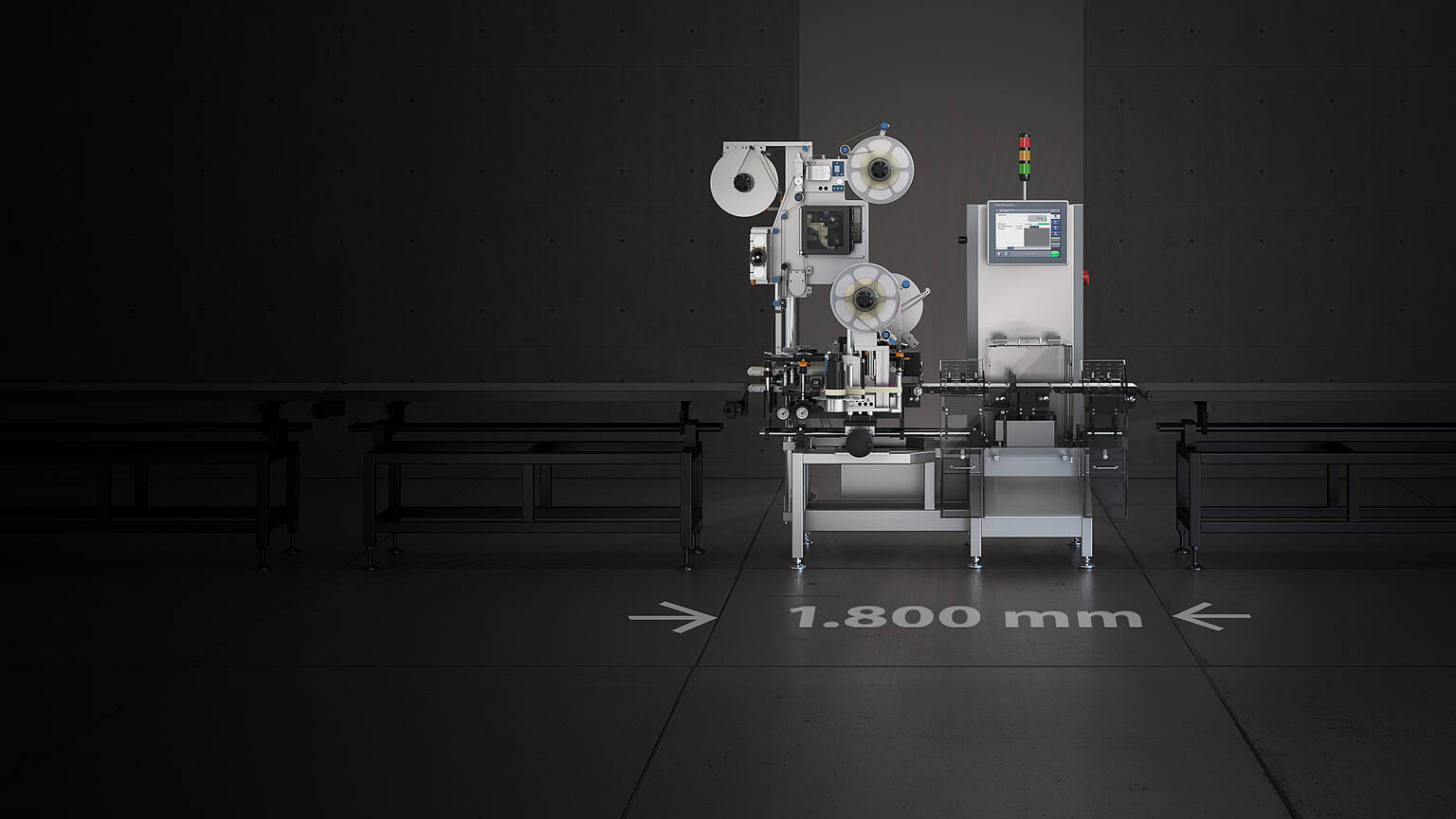

Machine readable coding ensures a globally unique product classification in the form of a serial number, combined with a Tamper-Evident label on each individual pack, to form the basis for consumer protection against counterfeit drugs. Serialisation and continuous aggregation provides transparency of product origin all the way to retail sale and creates trust and security in the market. The serialisation of individual boxes begins with the stable positioning on receipt from the cartoner.The labels are then applied as required to the front or back side, or the top of each folding box. Thanks to the compact design of the labeler, a Tamper-Evident label can be applied to prevent illegal opening of the original box. The TQS top conveyor system transports the folding boxes from the cartoner and has demonstrated maximum flexibility in adapting to the most varied of folding box dimensions

Aggregation: TQS provides optimal Track & Trace implementation

The series of machines in the Traceable Quality System (TQS) providesdelivers a format independent aggregation for all packaging levels (sets, cartons, palettes) tailored for the individual requirements of every customer. TQS enables the consolidation of the serial numbers of multiple individual packs into a separate unique serial number for the set. in In addition to semi-automatic aggregation of manually repacked cartons, where the operator places previously aggregated sets lengthwise into the shipping carton. The operator conveniently assigns the units from a lower packaging level (e.g., folding box) to a higher level (e.g., sets or shipping cartons). Therefore, a hierarchical relationship is created in the database.

Inspection Technology tailored to your needs

Our X-ray product line specializes in the detection of foreign bodies in foods and other products. At the same time the high-tech Wipotec X-ray scanners contribute to product optimisation and thus increasing productivity. They monitor filling levels, the shape and condition of packages, as well as check for damages, completeness and flawlessness of products and trays. Due to its compact design and modularity, our X-ray technology can be easily and swiftly integrated into your production lines.

We offer additional inspection solutions through metal detectors. They detect dangerous metal chips in packed and unpacked foods that are then ejected from the product flow.

Metal components in the packaging do not affect the measurement result, but can also be checked for completeness. The high-resolution X-ray images are shown on the display in real time and are used to log rejected products and optimize production. Metal detectors identify hazardous metal shavings in packaged and unpackaged food, which are then removed from the product flow.

First-Class Service at Wipotec

The professional service provided by Wipotec will provide you with comprehensive advice during the selection and setup of suitable components. The close technical collaboration with our team enables you to provide your customers with technically high-quality products together with sound know-how. Due to the bundling of development and manufacture on one single site, we can react flexibly to your requirements.

We find the right weighing and inspection modules for your application and support you during the space-saving integration of these modules into your devices. Our competent staff in technical support will support during the rest of the implementation process. However, the high quality and precision of our modules remains unchanged. Thanks to the first-class co-operation with Wipotec you can approach your customers confidently as a general contractor for the entire line.

Find the right solution for your application now!