Food Traceability: preventing food fraud and ineffective product recalls

With today’s complex food supply chain caused by changing industry processes and the consumer demand for foreign foods, tracing products effectively is more critical than ever for food safety and quality, and more challenging.

However, the industry is struggling to find an effective traceability system that would keep up with high production speeds. Flexible and modular traceability technology can solve this problem and help food manufacturers improve their processes, supply chain efficiency, emergency recall plan, without becoming a burden for production efficiency

Need more specific information on traceability solutions for your packaging line?

What is food traceability?

Food traceability refers to the systems that trace the flow of food through the food supply chain, including through production, processing, and distribution, and make it possible to locate a product at any stage of the food supply chain. Food traceability is important for a variety of reasons. The affected stakeholders are:

- Public safety – As an anti-counterfeiting measure for products, Food traceability reduces food fraud, which poses a risk to the public. It also allows for quick and efficient product recall, reducing the impact that contaminated food products can have on public health.

- Manufacturers – Tracing food products helps businesses manage emergency recall situations, reduce their liability, and improve consumers’ confidence in their brand. An adequate system that transmits accurate, consistent and complete product information can also decrease operating costs and augment productivity.

- Food supply chain - The supply chain benefits from food traceability because it makes the process more efficient, improves cash flow, and reduces waste.

- Consumers – Food traceability gives consumers confidence in the products they enjoy by letting them know its origins and components. It also minimises the risk of buying a fraudulent product, labelled under your brand name.

The benefits of food traceability during recalls

When a food risk is identified, it is important that authorities and businesses are able to trace the risk to its source so that they can prevent the affected products from being sold to consumers. Food traceability minimises disruption to trade by facilitating targeted product recalls and allowing brands to provide consumers with accurate information. During a product recall, the contaminated products are quickly located based on a serial number or batch number. With an effective traceability system in place, they can also be traced back through the food supply chain to figure out where the problem originated.

When it comes to emergency food product recalls, food traceability helps in the following ways:

- Preparation – Traceability provides businesses with a clear view of the supply chain, making it easier to plan for an emergency recall situation.

- Response – In the case of a recall, traceability improves the reaction of all parties because it's easier and quicker to locate the affected products.

- Recovery – While recovering after a food recall, implementation of an effective food traceability system increases consumer confidence and helps the brand rebuild its reputation.

- Prevention – Traceability makes it easier to identify where the problem occurred and to prevent it from happening again.

Would you like to learn how to implement an effective food traceability system, customised to the requirements of your specific application?

Food fraud risks and losses

Food fraud is a global issue that affects all consumers. It endangers their health by contaminating food products and sidestepping health and safety regulations. As food supply chains become more complex, for example, by using more ingredients and crossing the supply chains of multiple countries, the potential for food fraud increases. The World Health Organization estimates that 600 million people globally suffer from a foodborne disease as a result of consuming a contaminated product. In addition to being a safety issue, food fraud is estimated to cost the global food industry over $50 billion each year.

Common Types of Food Fraud

Not all food fraud is the same, but it is all potentially dangerous. The most common kinds of food fraud are:

With food fraud rising at an alarming speed, governments and food manufacturers alike start recognising the benefits and developing own Track and Trace systems. The global seafood industry, for instance, is now looking to create an adequate traceability scheme to prevent illegally sourced fish from entering seafood markets. To achieve this, an interoperable electronic system will trace the movement of fish through all supply chain touchpoints, from landing to retail.

Food traceability requirements

Since the traceability of food products is so critical, their traceability system must be accurate and complete. A food traceability system should be able to identify where a food product and its components were manufactured, packaged, and stocked, meaning that every stop on the supply chain has to get involved.

Today, food manufacturers are expected to be able to:

- Account for the origins and destinations of every product, including by weight of raw materials.

- Account for which material ended up in which finished product.

- Account for later production lots that contain products from earlier production lots.

- Make sure that the product packaging has unique lot numbers.

- Make sure that in the case of a food safety complaint, within four hours, the manufacturer can trace that product back to its ingredients and know where the rest of the ingredients went.

Additionally, a food traceability system must record and be able to identify information such as: raw materials, additives, ingredients, volume, quantity, weight, dimensions and expiry date.

Manufacturers must label products with unique identification codes that contain this information.

Additional regulations apply to specific sectors of food products, such as beef, seafood, honey, and olive oil. These foods are often targeted for food fraud, so the requirements are intended to help consumers verify the authenticity and origins of products.

There are also unique traceability rules for genetically modified organisms (GMOs) to ensure that the GM content of a product can be traced. Accurate labelling must be used so that consumers can make informed choices about whether or not to buy genetically modified products.

Is Food Traceability Legally Required?

Within the European Union, the General Food Law Regulation has established criteria for making sure that only safe food products make it onto the market. This includes the EU’s General Food Law of 2002, which made traceability mandatory for all food and animal feed businesses. Businesses must be able to identify their products‘ origins and destinations and make this information available to authorities.

In the United States, two main FDA regulations deal with food traceability: the Bioterrorism Act of 2002 and the Food Safety Modernization Act of 2011 (FSMA).

The Bioterrorism Act requires that each facility along the food supply chain be able to identify where a product came from as well as where it is going next, in what is called a “one step forward, one step back” traceability requirement.

The FSMA was introduced to expand upon the Bioterrorism Act by mandating the establishment and implementation of food safety systems in food supply chain facilities. This includes measures to prevent food product emergencies and a recall plan.

What is a food traceability system?

Traceability in the food industry is achieved through a Track and Trace system that includes a hardware solution and an appropriate IT infrastructure to enable product data transfer. In essence, product traceability rests on the following pillars:

- data generation,

- encoding,

- tracing and

- data management.

A traceability system is often implemented to enable anti-counterfeiting protection of products through securing product packaging. It provides a significant competitive advantage by minimising the instances of mislabelling and therefore enhancing customer trust and loyalty.

But just as importantly, an effective traceability system enables agile and efficient recall management, more control over a stock situation and enhanced production control.

Serialisation in the Food Industry

Serialisation of food products means assigning unique codes to food products. Serialisation makes it easier for both retailers and consumers to identify and track original products, increasing consumer confidence.

Some countries, including South Korea, are starting to include serialisation codes on food packaging. This enables manufacturers, retailers, and consumers to trace products easily from their origin, through the food supply chain, all the way to sale. It is predicted that serialisation in the food industry will increase within the next few years to minimise the impact of food scandals and to increase consumer safety and brand transparency.

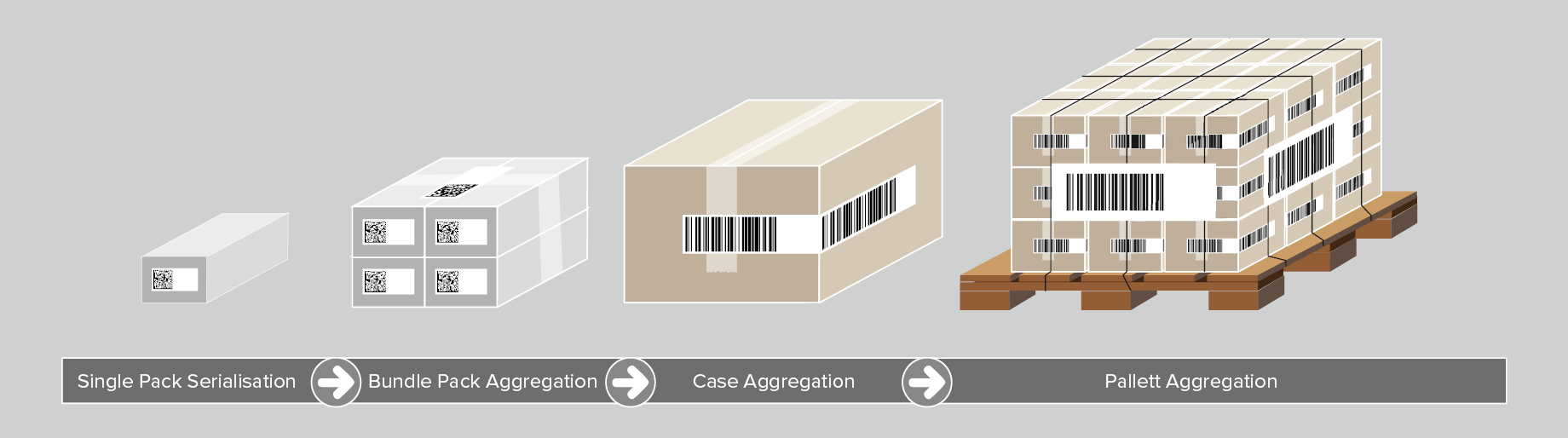

Aggregation in the Food Industry

Aggregation is an integral part of traceability in the food industry because it gives every step in the food supply chain the same information, making sure that there is only one source of truth. It allows food manufacturers to trace their products from production by maintaining parent-child relationships between the levels of food packaging. Here’s how it works:

- Beginning at the most basic level of packaging (retail packaging), a product is assigned a serialisation code.

- As packages are combined in the next level of packaging (up to shipping boxes and pallets), the serial codes are aggregated into a new code label for that packaging. This creates the so-called parent-child relationship, in which each individual package is assigned to a higher packaging unit.

- Each participant in the food supply chain, from the manufacturer to the distributor, receives the serialisation information from the previous step and registers the receipt of goods in the system.

- Each data aggregate is recorded in a database before it moves on to the next step in the supply chain.

Food Traceability System Hardware

A hardware solution can consist of different OEM modules to be integrated into an existing packaging line equipment. OEM hardware is flexible, and so it can be adapted to a variety of different products and packaging formats, and it also saves space on the production floor.

In its basic form, an OEM solution can consist of separate modules, such as coding, inspection and verification components that can be built into an already existing packaging equipment.

Food Traceability System IT Architecture

Traceability IT architecture should be designed to streamline traceability data exchange internally (i.e. on the company level) and externally (i. e. between supply chain partners). A traceability system makes sure that all parties along the food supply chain, have the same information about the products.

Food traceability enables food manufacturers to track a product or batch as it moves between processing, storage, and distribution, with new information recorded at each stage of the product flow.

As ingredients and products come from suppliers and are processed and distributed, a traceability system records and traces their path. It should include procedures for identifying producers, suppliers, distributors, and products. Additionally, the system can gather and record information about product ingredients, quality, origins, quantity, and labels.

Need more specific information on traceability solutions for your packaging line?

Relevant documents

Fighting food fraud together

With TQS, we provide flexible and scalable Track and Trace solutions for a diverse range of products and packaging formats. All TQS systems include advanced features to serialise and enable anti-counterfeit protection of food packaging without imposing an additional burden on production efficiency. Ease of operation and user-friendly design are at the core of TQS solutions.

High-Level Technology

- The modular and scalable design of TQS solutions offers flexibility to fulfil individual application requirements and integrate only those components that are necessary to meet specific serialisation and aggregation goals.

- Supports high production speeds of up to 500 pcs/min to make sure that Track and Trace implementation won’t slow down your manufacturing efficiency.

- Space-saving direct integration of machine components into machines of third-party manufacturers is especially beneficial for production facilities with less space.

- Ability to incorporate large data sets into a compact DataMatrix carrier to save space on the package.

- Sophisticated technology with simplified user interface and reduced operational complexity.

Need more information about Track and Trace or would like a consultation?

Strong industry partnerships

- Our extensive expertise and experience is a result of the successful implementation of over 3000 Track and Trace projects worldwide.

- Due to our close partnership with GS1, we can keep our customers informed about the latest developments and changes in Track and Trace regulations worldwide

- As a foundation and steering committee member of Open-SCS working group, we work towards standardisation of communication protocols and interfaces to enable compatibility of TQS solutions with any site-level system that suits product manufacturers’ needs.