Product Inspection for quality control and contaminations detection

Modular Design

for tailor-made solutions

Flexible Sensor Technologies

For your individual requirements

Diode Detector

Standard applications

Entry level sensor

Long lifetime

Option: Vision Cameras

VioX Camera

High speed applications

Maximum reliability for lower costs

7-year warranty, independent of operating hours or service contracts

Option: Vision Cameras

DFXr Camera

Challenging applications

Low density contaminants like bones

Remarkable detection capability

Option: Vision Cameras

Do you have a special challenge for us?

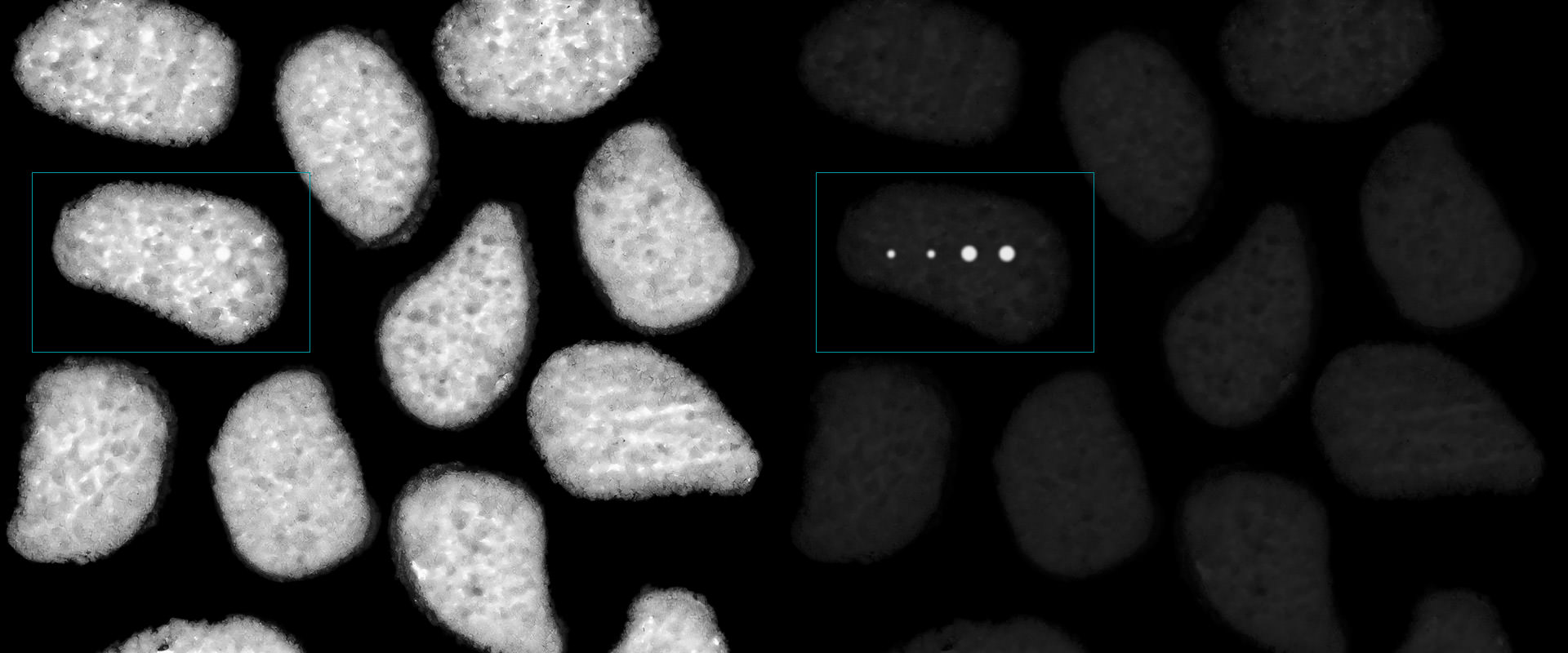

Image capture on a new level

The differences in image capture are crucial. Our TDI technology enables precise and detailed capture so that even the smallest contaminations are detected.

- 128 ×

Each pixel detected - 19″

Touchscreen - 0.1 mm

Resolution

16-Bit Technology

for maximum accuracy

A large number of X-ray systems work with 8-bit technology, which can differentiate between a total of 256 gray values. Our X-ray inspection systems use 16-bit technology. This means that our systems can differentiate between more than 60,000 gray values to distinguish between product and foreign bodies.

Precise inspection

of contaminants for all food industries

Best detection results

for food safety

Bone Detection in meat

Comparison Single- and Dual Frequency X-ray: Chicken Nuggets with artificial bone test card

Single Frequency X-rayDual Frequency X-ray

Do you have a special challenge for us?

Core Segments

- Smallest footprint

- Wide range of inspection widths

Modular Design

- Curtain-free

- Vertical offset

Modular Design

- Bulk flow

- Compact design

- Minimal product loss

Modular Design

- Radiation protection curtains

- Large chunky products

Modular Design

- Curtain-free

- Curved conveyors or S-conveyors

- No directional change

Modular Combination: Vision, Checkweigher and X-ray inspection as a space saving integrated system

Optical and X-ray inspection

Checkweighing and X-ray inspection